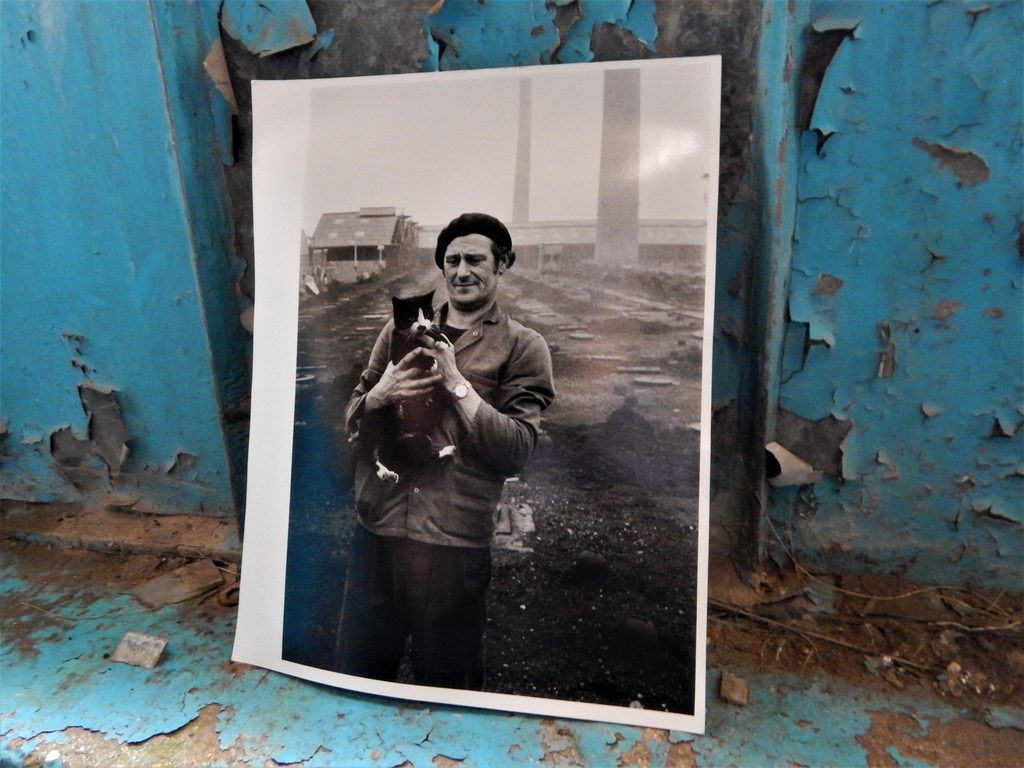

Stewartby brickworks was home to the world's biggest kiln and produced 18 million bricks at the height of production.

Originally called “Wootton Pillinage”, the brickworks were renamed Stewartby in 1937 in recognition of the Stewart family who had been instrumental in developing the brickworks.

The firm became London Brick Company and Forders Limited in 1926, and shortened to London Brick Company in 1936.

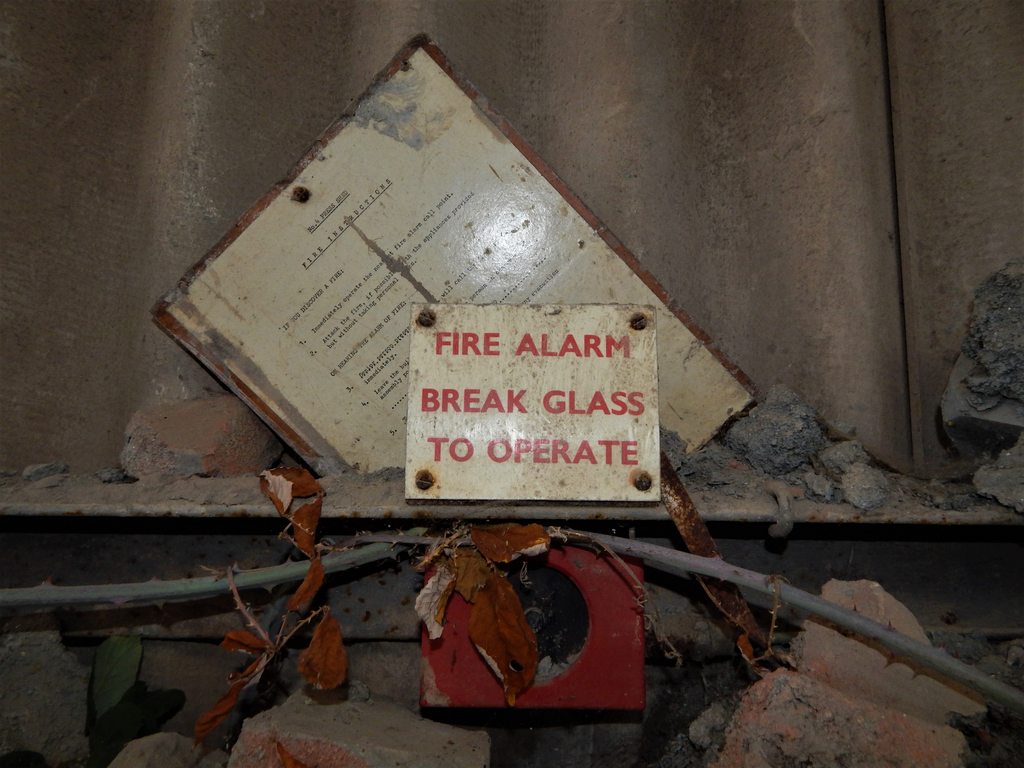

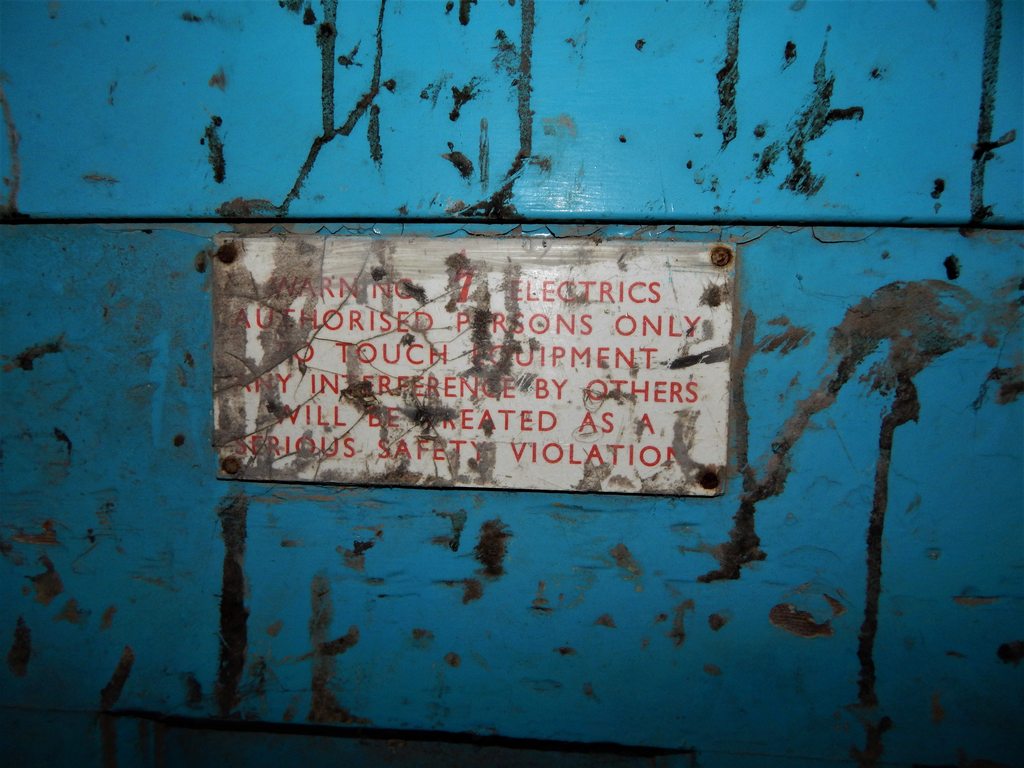

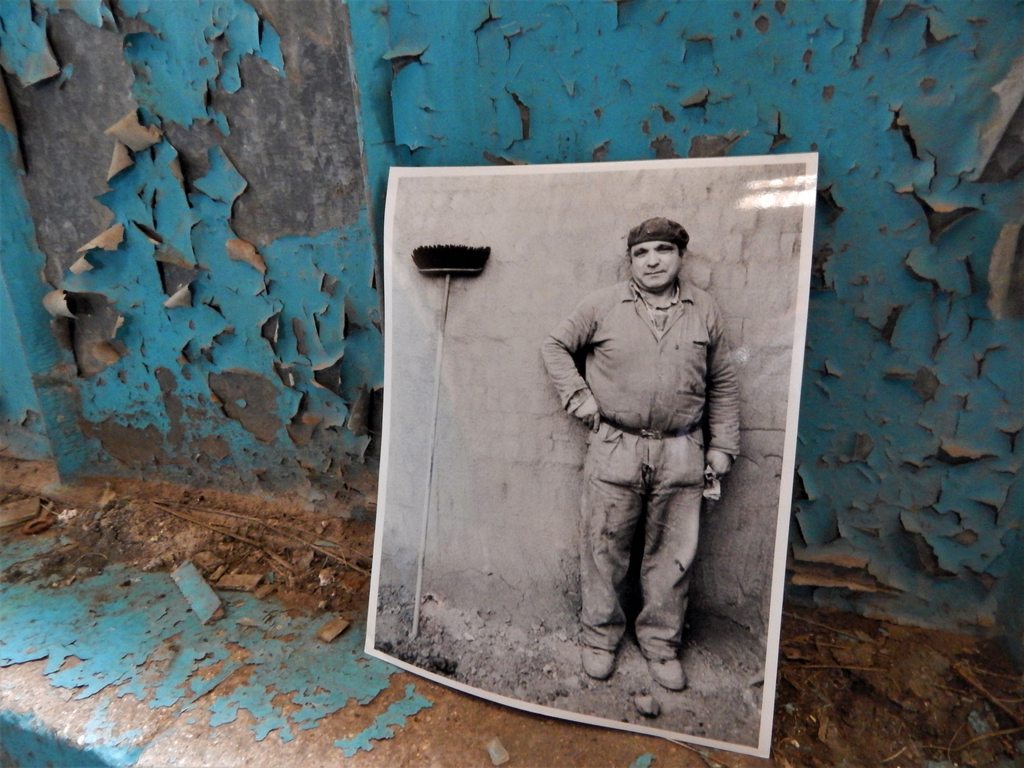

At its peak, London Brick Company had its own ambulance and fire crews, a horticultural department and a photographic department, as well as its own swimming pool inside the factory, and ran a number of sports clubs.

More than £1 million was spent on Stewartby Brickworks in 2005-7 in an attempt to reduce sulphur dioxide emissions, however the emissions were unable to be reduced enough to fall into accordance with UK guidelines. As a result, the brickworks had to close, which lead to 217 people losing their jobs.

I visited here with jsp77 a few months back on a very wet day. Despite the rain it was a very enjoyable mooch.

Thanks for looking,

Rubex

Originally called “Wootton Pillinage”, the brickworks were renamed Stewartby in 1937 in recognition of the Stewart family who had been instrumental in developing the brickworks.

The firm became London Brick Company and Forders Limited in 1926, and shortened to London Brick Company in 1936.

At its peak, London Brick Company had its own ambulance and fire crews, a horticultural department and a photographic department, as well as its own swimming pool inside the factory, and ran a number of sports clubs.

More than £1 million was spent on Stewartby Brickworks in 2005-7 in an attempt to reduce sulphur dioxide emissions, however the emissions were unable to be reduced enough to fall into accordance with UK guidelines. As a result, the brickworks had to close, which lead to 217 people losing their jobs.

I visited here with jsp77 a few months back on a very wet day. Despite the rain it was a very enjoyable mooch.

Thanks for looking,

Rubex