- Joined

- Jan 6, 2013

- Messages

- 5,680

- Reaction score

- 11,382

1. The History

Bole Hill Millstone Quarry just outside Hathersage and Upper Padley, above Grindleford Station in Derbyshire. Millstones have been produced in the county since at least the 13th century. The eastern edges of Millstone, Burbage and Stanage were all extensively quarried. Bole Hill was chosen for quarrying due to the quality of the rock and millstones, grindstones and crushing stones were made here for over 600 years. In medieval times the local stone was used for millstones for grinding flour but then when the move to white bread came, gritstone fell out of favour due to it making the flour grey. From then on, the stones were used for industrial grinding. Eventually this market collapsed due to cheaper imports from France. The quarry was almost abandoned overnight and the pulp-stones we see here today were left in-situ. They were due to be exported to Scandinavia for use in crushing wood into pulp for the paper industry. There would have been some wooden structures at the quarry, but these have long rotted away.

However, the quarry was given a lease of life in 1901, with the passing of the Derwent Valley Water Act and the commitment to construct the Howden and Derwent Dams. Initially the stone was to come from Ladybower Clough, but objections forced the Derwent Valley Water Board to source the stone from elsewhere. Hence in November 1901 the Board purchased 52 acres of land at Bole Hill from Mr Shuttleworth of Hathersage, and the incumbent tenant, Mr Cooper, paid £20. The area was chosen as the beds of stone were near to the surface at an average depth of approximately 65 feet and the quarry face an impressive 1,200 yards long. The estimated 2.4 million tons building stone was considered to be top grade due to the silica and feldspar composition of the millstone grit, making it both perfect and plentiful for the construct the two aforementioned dams.

A standard gauge railway was constructed along the quarry face, which culminated in marshalling area for the trucks. A cutting then led to the summit of the 300-foot incline which ran down the hill to link with the Midland Railway Hope Valley Line. An army of workers were brought in from Sheffield on early morning specials trains while workers from further afar were put up in tin bungalows adjacent to the site, along with a library, recreation room and mess rooms. The quarry commenced operations in 1903 and in its seven and a half years life, more than 1.25 million tons of stone were extracted. Workshops for dressing the large blocks which weighted between 20 and 30 tons were built adjacent to the quarry face. Meanwhile the rubble and filler stone was loaded by two steam-powered cranes straight into specially built trucks, which were then lowered down the incline. Its 1-in-3 gradient made this a hazardous operation and was controlled by a brakeman on the drum of the winding wheel. As each loaded truck was lowered it raised an empty truck up from the bottom. Once at the bottom the wagons were shunted into the sidings before being hauled up the Hope Valley line to the specially constructed "Waterworks Sidings" at Thornhill. They were then taken up the Bamford and Howden Railway by the D.V.W.B. owned locomotives to the construction sites.

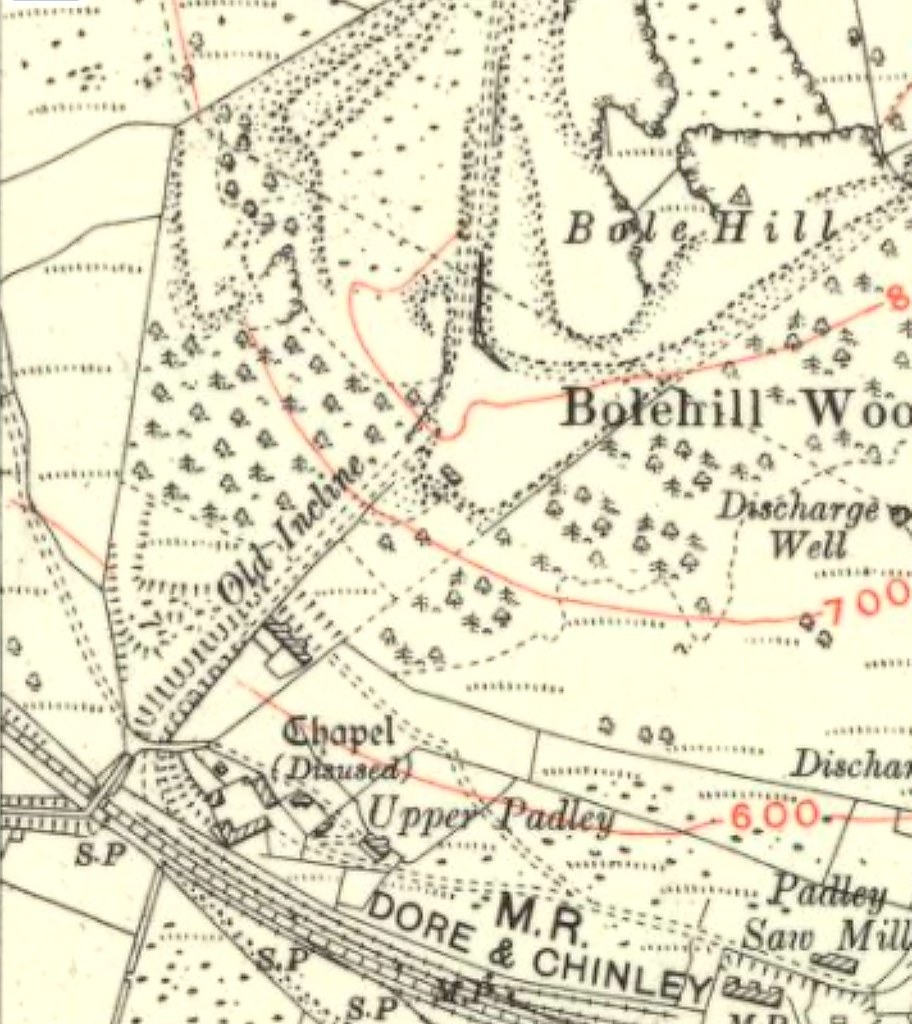

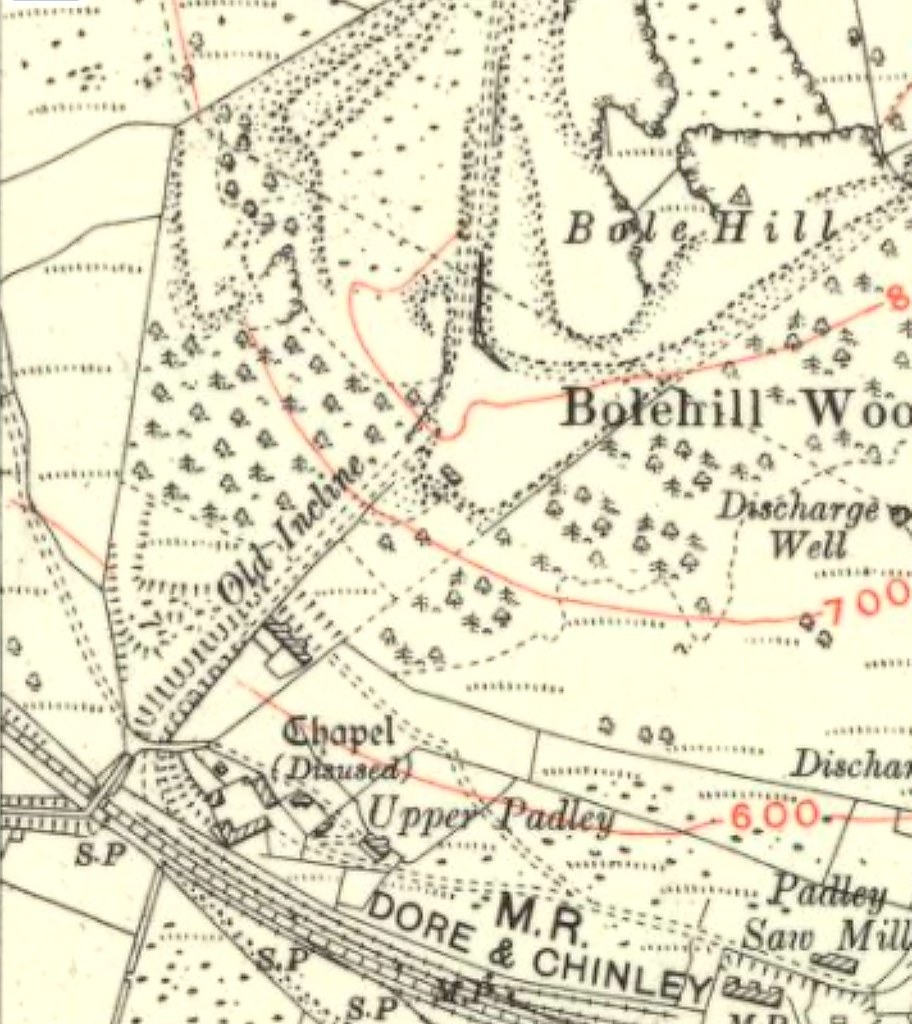

OS Map extract showing the incline in relation to Grindleford Station:

By October 1905 there were some 439 men were employed at the quarry, operating two 12-ton cranes, nine 7-ton cranes, one 5-ton crane, three locomotives, the winding drum and the almost 100 tipper wagons. Disaster struck on two occasions when two men were killed whilst working in the quarry. One fell and died from concussion while the other man died in a cutting when three loaded trucks broke loose and careered into an area where around 20 men were working. Production ceased in December 1910 (although some small quantities of stone continued to be quarried and be sent up to Derwent up to April 1914) and the majority of the heavy plant removed from the site in early 1911. The quarry formally closed in September 1914 and the final plant and materials removed. The DVWB had planned to build a housing estate in the quarry workings but this never came to fruition, allowing them the option to quarry the still extensive resources of stone, should the demand arise. There were future developments in 1935, with the construction of the Ladybower Reservoir, but the mainly earth dam meant little stone would be required. Hence the old quarry proved little worth to DVWB who very generously gifted the area to the National Trust in 1947.

The winding drum circa 1904 and to the right, two locomotives standing back-to-back

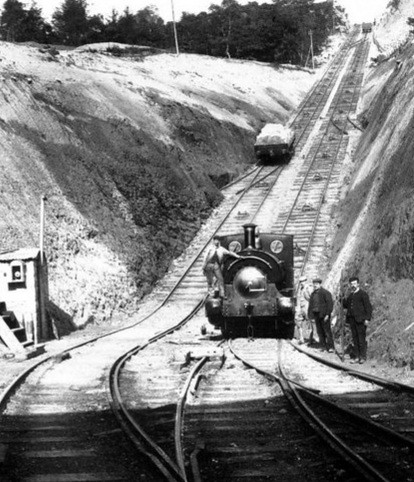

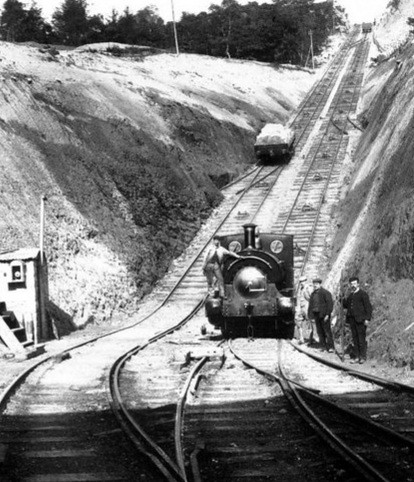

Looking up the incline with a loaded truck coming down on the left. circa 1904:

Marshalling sidings circa 1910:

2. The Explore

Been coming here for a number of years. Only really dawned on me recently that this place would be worth a report. Looking into the history of the site and it made me realise there was more there than at first thought. It's a fantastic place and although nature has taken the quarry back, with an imaginative eye, you can start to imagine what the quarry would have looked like in its heyday.

3. The Pictures

Starting at the top of the quarry, there are literally hundreds of old millstones piled up::

img2691 by HughieDW, on Flickr

img2691 by HughieDW, on Flickr

img2648 by HughieDW, on Flickr

img2648 by HughieDW, on Flickr

img2651 by HughieDW, on Flickr

img2651 by HughieDW, on Flickr

img2652 by HughieDW, on Flickr

img2652 by HughieDW, on Flickr

img2661 by HughieDW, on Flickr

img2661 by HughieDW, on Flickr

img2662 by HughieDW, on Flickr

img2662 by HughieDW, on Flickr

img2680 by HughieDW, on Flickr

img2680 by HughieDW, on Flickr

img2689 by HughieDW, on Flickr

img2689 by HughieDW, on Flickr

Possibly the biggest millstone I saw:

Sandstone quarry 11 by HughieDW, on Flickr

Sandstone quarry 11 by HughieDW, on Flickr

Old stone trough:

Sandstone quarry 13 by HughieDW, on Flickr

Sandstone quarry 13 by HughieDW, on Flickr

And the upper quarry itself:

Sandstone quarry 14 by HughieDW, on Flickr

Sandstone quarry 14 by HughieDW, on Flickr

Stone gable end of an old quarryman's hut:

Sandstone quarry 15 by HughieDW, on Flickr

Sandstone quarry 15 by HughieDW, on Flickr

Slightly further down we come to the old powder house:

Bolehill Store 01 by HughieDW, on Flickr

Bolehill Store 01 by HughieDW, on Flickr

Bolehill Store 02 by HughieDW, on Flickr

Bolehill Store 02 by HughieDW, on Flickr

Bolehill Store 03 by HughieDW, on Flickr

Bolehill Store 03 by HughieDW, on Flickr

Bolehill 02 by HughieDW, on Flickr

Bolehill 02 by HughieDW, on Flickr

Moving on to where the stone for the dams was quarried:

Bolehill 03 by HughieDW, on Flickr

Bolehill 03 by HughieDW, on Flickr

This was either a crane base or a loading platform:

Bolehill 04 by HughieDW, on Flickr

Bolehill 04 by HughieDW, on Flickr

Bolehill 05 by HughieDW, on Flickr

Bolehill 05 by HughieDW, on Flickr

Bolehill 06 by HughieDW, on Flickr

Bolehill 06 by HughieDW, on Flickr

Bolehill 07 by HughieDW, on Flickr

Bolehill 07 by HughieDW, on Flickr

The cutting heading towards the top of the incline:

Bolehill 09 by HughieDW, on Flickr

Bolehill 09 by HughieDW, on Flickr

Bolehill 10 by HughieDW, on Flickr

Bolehill 10 by HughieDW, on Flickr

Bole Hill Millstone Quarry just outside Hathersage and Upper Padley, above Grindleford Station in Derbyshire. Millstones have been produced in the county since at least the 13th century. The eastern edges of Millstone, Burbage and Stanage were all extensively quarried. Bole Hill was chosen for quarrying due to the quality of the rock and millstones, grindstones and crushing stones were made here for over 600 years. In medieval times the local stone was used for millstones for grinding flour but then when the move to white bread came, gritstone fell out of favour due to it making the flour grey. From then on, the stones were used for industrial grinding. Eventually this market collapsed due to cheaper imports from France. The quarry was almost abandoned overnight and the pulp-stones we see here today were left in-situ. They were due to be exported to Scandinavia for use in crushing wood into pulp for the paper industry. There would have been some wooden structures at the quarry, but these have long rotted away.

However, the quarry was given a lease of life in 1901, with the passing of the Derwent Valley Water Act and the commitment to construct the Howden and Derwent Dams. Initially the stone was to come from Ladybower Clough, but objections forced the Derwent Valley Water Board to source the stone from elsewhere. Hence in November 1901 the Board purchased 52 acres of land at Bole Hill from Mr Shuttleworth of Hathersage, and the incumbent tenant, Mr Cooper, paid £20. The area was chosen as the beds of stone were near to the surface at an average depth of approximately 65 feet and the quarry face an impressive 1,200 yards long. The estimated 2.4 million tons building stone was considered to be top grade due to the silica and feldspar composition of the millstone grit, making it both perfect and plentiful for the construct the two aforementioned dams.

A standard gauge railway was constructed along the quarry face, which culminated in marshalling area for the trucks. A cutting then led to the summit of the 300-foot incline which ran down the hill to link with the Midland Railway Hope Valley Line. An army of workers were brought in from Sheffield on early morning specials trains while workers from further afar were put up in tin bungalows adjacent to the site, along with a library, recreation room and mess rooms. The quarry commenced operations in 1903 and in its seven and a half years life, more than 1.25 million tons of stone were extracted. Workshops for dressing the large blocks which weighted between 20 and 30 tons were built adjacent to the quarry face. Meanwhile the rubble and filler stone was loaded by two steam-powered cranes straight into specially built trucks, which were then lowered down the incline. Its 1-in-3 gradient made this a hazardous operation and was controlled by a brakeman on the drum of the winding wheel. As each loaded truck was lowered it raised an empty truck up from the bottom. Once at the bottom the wagons were shunted into the sidings before being hauled up the Hope Valley line to the specially constructed "Waterworks Sidings" at Thornhill. They were then taken up the Bamford and Howden Railway by the D.V.W.B. owned locomotives to the construction sites.

OS Map extract showing the incline in relation to Grindleford Station:

By October 1905 there were some 439 men were employed at the quarry, operating two 12-ton cranes, nine 7-ton cranes, one 5-ton crane, three locomotives, the winding drum and the almost 100 tipper wagons. Disaster struck on two occasions when two men were killed whilst working in the quarry. One fell and died from concussion while the other man died in a cutting when three loaded trucks broke loose and careered into an area where around 20 men were working. Production ceased in December 1910 (although some small quantities of stone continued to be quarried and be sent up to Derwent up to April 1914) and the majority of the heavy plant removed from the site in early 1911. The quarry formally closed in September 1914 and the final plant and materials removed. The DVWB had planned to build a housing estate in the quarry workings but this never came to fruition, allowing them the option to quarry the still extensive resources of stone, should the demand arise. There were future developments in 1935, with the construction of the Ladybower Reservoir, but the mainly earth dam meant little stone would be required. Hence the old quarry proved little worth to DVWB who very generously gifted the area to the National Trust in 1947.

The winding drum circa 1904 and to the right, two locomotives standing back-to-back

Looking up the incline with a loaded truck coming down on the left. circa 1904:

Marshalling sidings circa 1910:

2. The Explore

Been coming here for a number of years. Only really dawned on me recently that this place would be worth a report. Looking into the history of the site and it made me realise there was more there than at first thought. It's a fantastic place and although nature has taken the quarry back, with an imaginative eye, you can start to imagine what the quarry would have looked like in its heyday.

3. The Pictures

Starting at the top of the quarry, there are literally hundreds of old millstones piled up::

img2691 by HughieDW, on Flickr

img2691 by HughieDW, on Flickr img2648 by HughieDW, on Flickr

img2648 by HughieDW, on Flickr img2651 by HughieDW, on Flickr

img2651 by HughieDW, on Flickr img2652 by HughieDW, on Flickr

img2652 by HughieDW, on Flickr img2661 by HughieDW, on Flickr

img2661 by HughieDW, on Flickr img2662 by HughieDW, on Flickr

img2662 by HughieDW, on Flickr img2680 by HughieDW, on Flickr

img2680 by HughieDW, on Flickr img2689 by HughieDW, on Flickr

img2689 by HughieDW, on FlickrPossibly the biggest millstone I saw:

Sandstone quarry 11 by HughieDW, on Flickr

Sandstone quarry 11 by HughieDW, on FlickrOld stone trough:

Sandstone quarry 13 by HughieDW, on Flickr

Sandstone quarry 13 by HughieDW, on FlickrAnd the upper quarry itself:

Sandstone quarry 14 by HughieDW, on Flickr

Sandstone quarry 14 by HughieDW, on FlickrStone gable end of an old quarryman's hut:

Sandstone quarry 15 by HughieDW, on Flickr

Sandstone quarry 15 by HughieDW, on FlickrSlightly further down we come to the old powder house:

Bolehill Store 01 by HughieDW, on Flickr

Bolehill Store 01 by HughieDW, on Flickr Bolehill Store 02 by HughieDW, on Flickr

Bolehill Store 02 by HughieDW, on Flickr Bolehill Store 03 by HughieDW, on Flickr

Bolehill Store 03 by HughieDW, on Flickr Bolehill 02 by HughieDW, on Flickr

Bolehill 02 by HughieDW, on FlickrMoving on to where the stone for the dams was quarried:

Bolehill 03 by HughieDW, on Flickr

Bolehill 03 by HughieDW, on FlickrThis was either a crane base or a loading platform:

Bolehill 04 by HughieDW, on Flickr

Bolehill 04 by HughieDW, on Flickr Bolehill 05 by HughieDW, on Flickr

Bolehill 05 by HughieDW, on Flickr Bolehill 06 by HughieDW, on Flickr

Bolehill 06 by HughieDW, on Flickr Bolehill 07 by HughieDW, on Flickr

Bolehill 07 by HughieDW, on FlickrThe cutting heading towards the top of the incline:

Bolehill 09 by HughieDW, on Flickr

Bolehill 09 by HughieDW, on Flickr Bolehill 10 by HughieDW, on Flickr

Bolehill 10 by HughieDW, on Flickr

Bolehill 11

Bolehill 11 Bolehill 12

Bolehill 12 Bolehill 15

Bolehill 15 Bolehill 16

Bolehill 16 Bolehill 17

Bolehill 17 Bolehill 19

Bolehill 19 Bolehill 21

Bolehill 21 Bolehill 22

Bolehill 22 Bolehill 23

Bolehill 23 Bolehill 25

Bolehill 25 Bolehill 24

Bolehill 24