Fantastic stuff history remade thank youNot sure Ill get away with this as but this may be of interest to some of you.

Im guessing as you are looking at this site you know what a Nissen hut is? Ok Ill assume you do & you know what one looks like

Iv run an structural & architectural steelworks for a fair while now & while its generally pretty dull occasionally something comes along that is a but different. Having been in many a nissen hut as Im sure most of you have I was quite excited when this dropped on my desk.

Anyway like a long distance runner with a split personality Im getting ahead of myself now.

Nissen huts were developed during the First World War by Major Peter Norman Nissen of the 29th Company, Royal Engineers. The design was formalized after three prototypes were constructed in April 1916. At least 100,000 were produced in World War 1. Nissen patented his design in 1916. For this work he was promoted to Colonel, awarded the DSO (Distinguished Service Order) and paid royalties on the sale of huts after the war. Many huts were used as temporary housing after the Second World War.

So how do we get involved? an inquiry arrives from a client that wants 2 replica nissen huts to stand where 2 originally stood on ex military land, but these 2 are to be houses (for the clients parents & inlaws) we win the quote then this is passed on to myself for drawing.

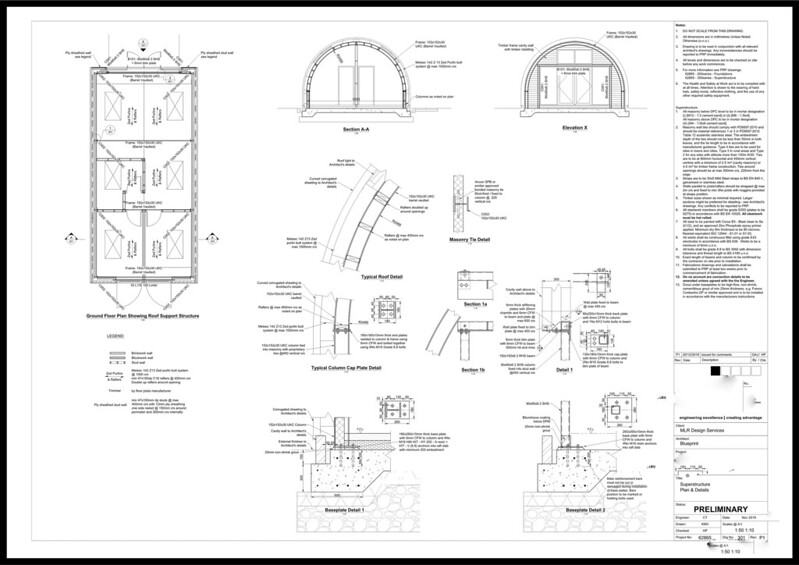

We are not structural engineers so the basic design & section sizes have been specified by someone else, this is the drawing we receive

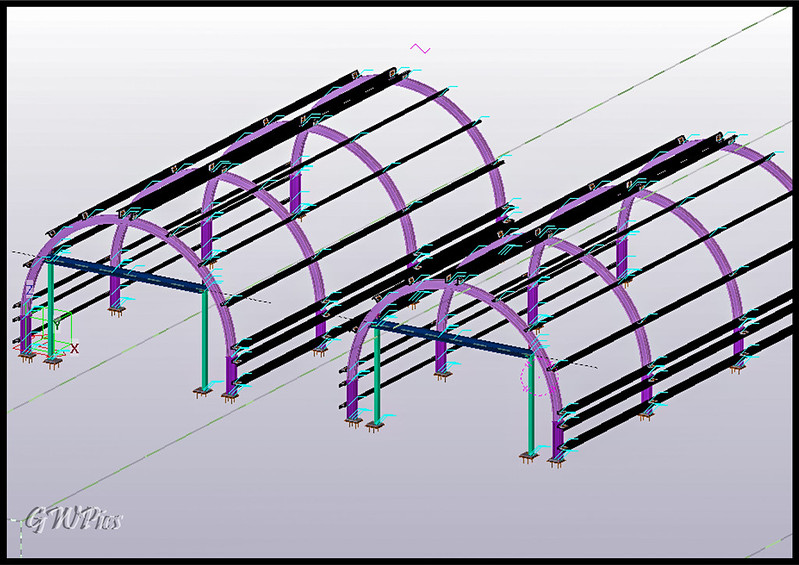

From this I essentially redraw the same thing in a 3d cad package (tekla structures), this needs to be done for 2 reasons

1 - to produce 2d drawings fabrication shop can read & produce steel members from

2 - (& this is now slightly controversial) to satisfy CE marking the European standard to which we are a complying company.

the 3 d modelling process looks like this.

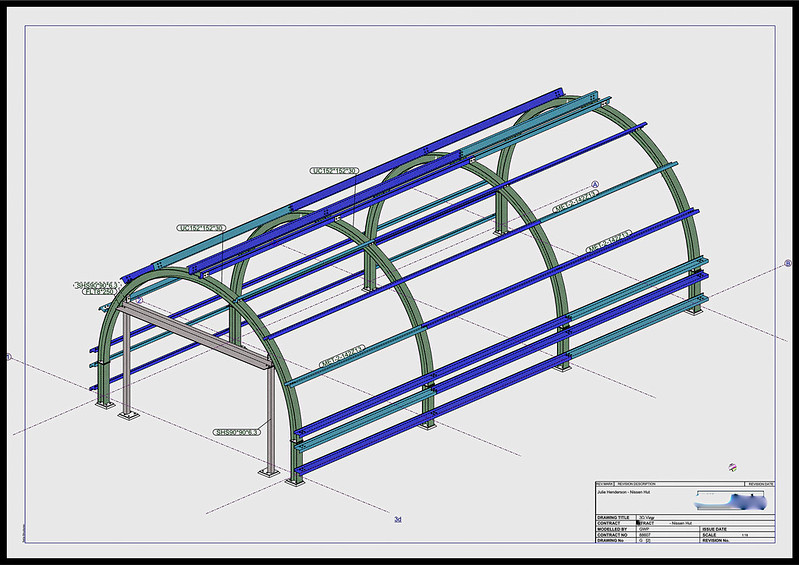

From this I can produce 3d drawings along with plans, elevations & any details to send to client.

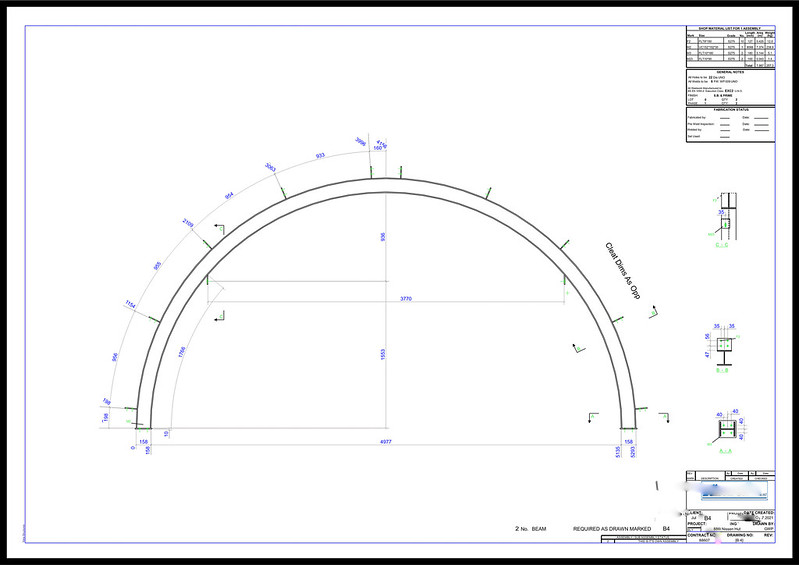

I then produce 2d drawings for our fabrication shop & in this case for the section benders. unfortunately there are few places in the UK that can now bend steel beams to your requirements & we are not one of them so this element of the work is done out house.

Once we receive the oversize curved members its down to our fabrication crew to cut these & weld on all plates etc to match my drawing.

The completed members then go through our paint process & await erection.

Now as well as being manager its true that I like a good erection! Iv been erecting most my life tbh so a bit of a coincidence left me with the task of erecting our first hut today which secretly I really wanted to do lol.

We did this using our rather superb HIAB lorry which can lift around 1T at 18.5m so this was nothing to it,

We atarted by assembling the curved members to their short vertical sections on the floor, then lifted the first frame onto pre installed holding down bolts.

The frames were tied together with cold rolled material (the sort of thing you see holding roof sheets in a factory unit) but alarmingly had no lateral bracing, so was all a bit "swayey" as I found out while climbing on it to tighten bolts. anyway just like mechano as they say this is the rest of the building going up.

And the completed steel frame, not bad for 4hr work for 2 of us

So I was quite pleased with that until I read this...Nissen Huts came in three sizes: 16ft, 24ft and 30ft (width). The 16ft span usually had 6 bays, making an overall length of 36ft 6 ½ inches, though due to the design and construction they could be made up of any number of bays. They were cheap and easy to put up. A 16ft hut could be put up in 6 hours by 4 men. The record is 1 hour and 27 minutes.

Ill now go & drown my sorrows, but I will try & get some pics of this when its finished for u all.

Thanks for looking

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to build a Nissen hut 2021

- Thread starter BikinGlynn

- Start date

Help Support Derelict Places:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Amazing post!

I'm also very impressed with the bending! I specify huge radius curves on steelwork (I design a lot of Amazon warehouses with curved roofs) and they grumble at the radii, so hats off to whoever got those so tight!

I'd also like to see it further progressed if you're allowed to share

I'm also very impressed with the bending! I specify huge radius curves on steelwork (I design a lot of Amazon warehouses with curved roofs) and they grumble at the radii, so hats off to whoever got those so tight!

I'd also like to see it further progressed if you're allowed to share

I agree but they pail in to insignificance with the place I worked before retiring. The place is Round and the roof curved . Have a read Diamond Light Source it was an explore I did while working. I've been to some steel fabricators and I'm amazed at what they can do nowAmazing post!

I'm also very impressed with the bending! I specify huge radius curves on steelwork (I design a lot of Amazon warehouses with curved roofs) and they grumble at the radii, so hats off to whoever got those so tight!

I'd also like to see it further progressed if you're allowed to share

- Joined

- Jun 7, 2014

- Messages

- 3,111

- Reaction score

- 5,056

I agree but they pail in to insignificance with the place I worked before retiring. The place is Round and the roof curved . Have a read Diamond Light Source it was an explore I did while working. I've been to some steel fabricators and I'm amazed at what they can do now

thats quite impressive but yes pretty much anything is possible these days with cnc machines etc.

- Joined

- May 14, 2018

- Messages

- 1,305

- Reaction score

- 954

I may have mentioned before that, in the early 1950s in Plymouth, Nissen huts with shop-front syle ends were erected to temporarily house retail businesses whose premises had been destroyed in the WWII bombing. The bombed areas were being cleared, to make way for the town planners' dream of the new Plymouth.

Similar threads

- Replies

- 5

- Views

- 267

- Replies

- 0

- Views

- 1K

- Replies

- 1

- Views

- 390