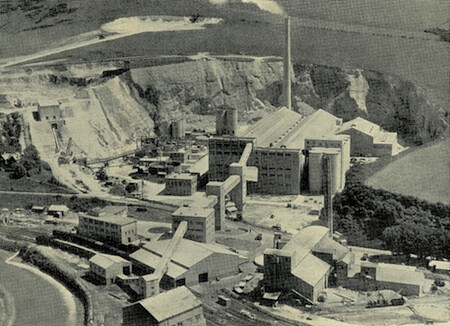

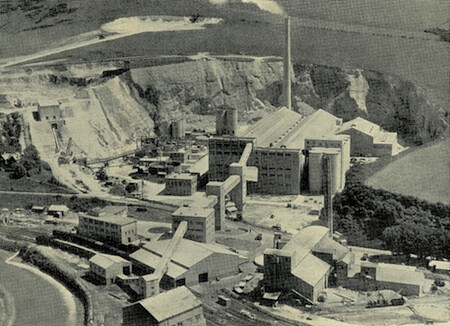

Shoreham Cement Works

With operation starting in 1883 the works' began life as the Beeding Portland Cement Company with a production of over 140 tonnes of cement per week. The strategic location of this works allowed for supplies to be bought in via the Adur such as, Coal - for powering the works, Sand, Clay and Gypsum - for production of cement, by boat. The early 1900's saw the first of many expansions to the cement works with the introduction of new kilns (A1 and A2 Installed in 1900), rawmills and washmills. These first years also saw the extension and addition of railway lines to the works heading further inland with some of them still visible if you walk along the river today. These modifications allowed for the plant to kick out around 800 tonnes of cement product weekly. A third cement kiln (A3) was added in 1911 supplied by Krupp rather than the first two provided by FLSmidth. As the 1930's came around pressure from the Second World War forced the works to close during these times. Following the war the cement works were demolished and completely rebuilt re-opening as Shoreham Cement Works. The works now had a new design with a, Chalk crushing plant, Kiln house (housing Kilns C1 and C2), Chalk crushing plant, storage warehouse for raw materials shipped in, cement mill and storage silos. This new design created many job opportunities within the area and allowed the works to produce over 500 tonnes of cement a day. The works continued in this state on wards to the closure in 1991 with minor modifications to increase efficiency but after so many years its time was up with the high pollution levels and outdated design a plant like this could no longer operate in a modern age. Since closure not much has happened. The area surrounding the plant has become home to numerous lorries which are surplus to their requirement or simply require repairs. The quarry which now scars the landscape has remained relatively untouched providing habitats to animals along its edge.

We had been close to visiting Shoreham many times in the past, but finally got to it this Summer. After camping nearby, we made our way through the cliff surrounded wasteland in the early light to get as close as we could. I really enjoyed exploring the factory and seeing some parts that haven't been looked at for a while.

Entering the epic kiln hall.

Control room in the kiln hall.

Looking towards the conveyor side of the kiln hall, where pipes would feed in the materials that would enter the kilns.

Moving away from the kiln hall towards other chambers in the facility where the process would finish.

Cement mill.

Motors that would power the cement mixers in the space beside them.

To conclude, a shot looking back over the building from the roof.

Here's the link to our documentary styled video showcasing Shoreham Cement Works. We cover the factory's past, present and future through cinematics and narration:

https://youtu.be/bfRsdEGEYzg

Thanks for reading

With operation starting in 1883 the works' began life as the Beeding Portland Cement Company with a production of over 140 tonnes of cement per week. The strategic location of this works allowed for supplies to be bought in via the Adur such as, Coal - for powering the works, Sand, Clay and Gypsum - for production of cement, by boat. The early 1900's saw the first of many expansions to the cement works with the introduction of new kilns (A1 and A2 Installed in 1900), rawmills and washmills. These first years also saw the extension and addition of railway lines to the works heading further inland with some of them still visible if you walk along the river today. These modifications allowed for the plant to kick out around 800 tonnes of cement product weekly. A third cement kiln (A3) was added in 1911 supplied by Krupp rather than the first two provided by FLSmidth. As the 1930's came around pressure from the Second World War forced the works to close during these times. Following the war the cement works were demolished and completely rebuilt re-opening as Shoreham Cement Works. The works now had a new design with a, Chalk crushing plant, Kiln house (housing Kilns C1 and C2), Chalk crushing plant, storage warehouse for raw materials shipped in, cement mill and storage silos. This new design created many job opportunities within the area and allowed the works to produce over 500 tonnes of cement a day. The works continued in this state on wards to the closure in 1991 with minor modifications to increase efficiency but after so many years its time was up with the high pollution levels and outdated design a plant like this could no longer operate in a modern age. Since closure not much has happened. The area surrounding the plant has become home to numerous lorries which are surplus to their requirement or simply require repairs. The quarry which now scars the landscape has remained relatively untouched providing habitats to animals along its edge.

We had been close to visiting Shoreham many times in the past, but finally got to it this Summer. After camping nearby, we made our way through the cliff surrounded wasteland in the early light to get as close as we could. I really enjoyed exploring the factory and seeing some parts that haven't been looked at for a while.

Entering the epic kiln hall.

Control room in the kiln hall.

Looking towards the conveyor side of the kiln hall, where pipes would feed in the materials that would enter the kilns.

Moving away from the kiln hall towards other chambers in the facility where the process would finish.

Cement mill.

Motors that would power the cement mixers in the space beside them.

To conclude, a shot looking back over the building from the roof.

Here's the link to our documentary styled video showcasing Shoreham Cement Works. We cover the factory's past, present and future through cinematics and narration:

https://youtu.be/bfRsdEGEYzg

Thanks for reading